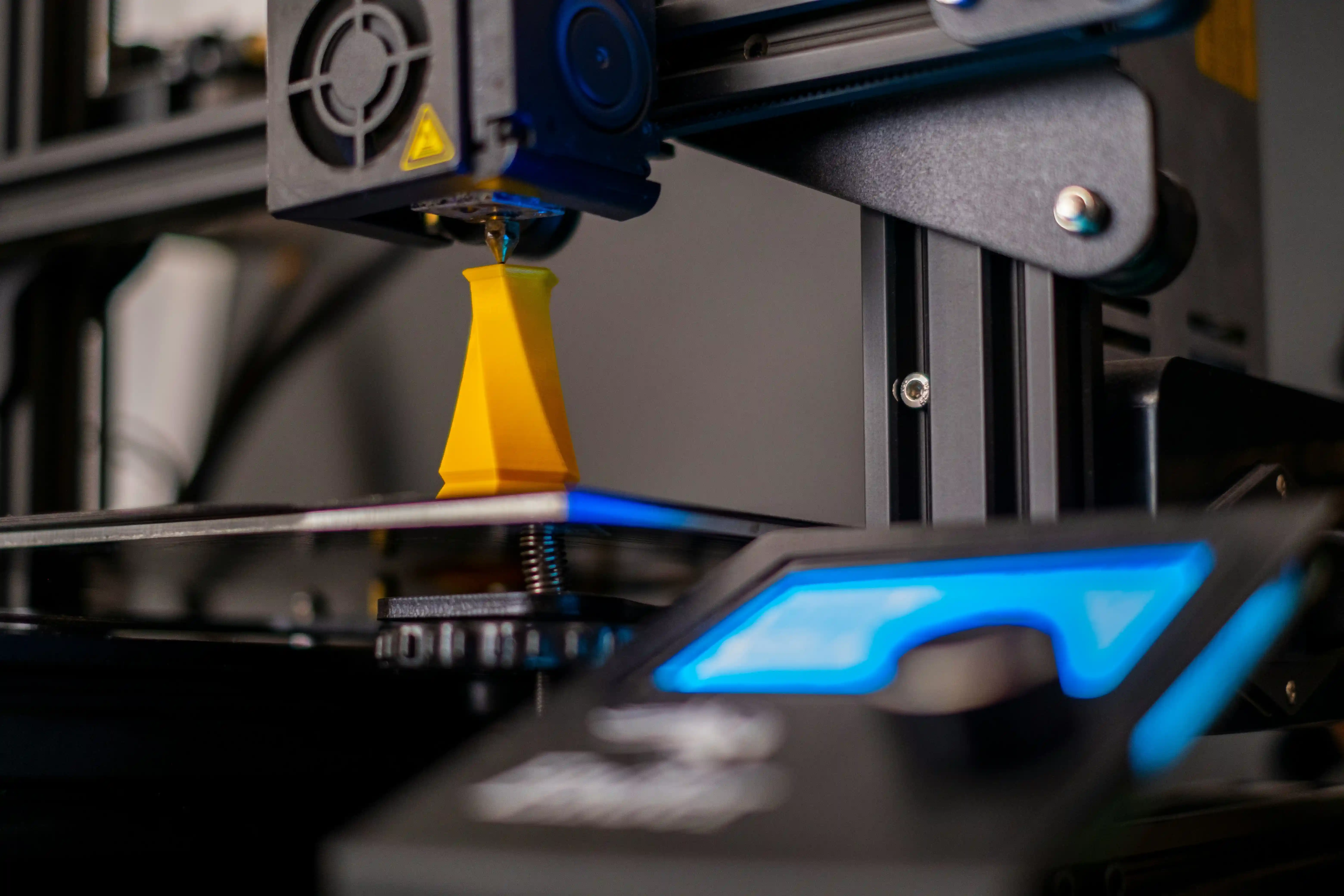

3D printing's no longer just for big-budget labs—engineers all over India now use it to get parts made fast and accurately. Whether it's an automotive team testing a new design or a healthcare company needing a custom device, additive manufacturing is delivering real, practical solutions for both prototypes and production runs.

Knowing the differences between FDM, SLA, SLS, and MJF, plus how to pick materials and suppliers, can save you a lot of time and money. Each method has its perks, depending on what you need—speed, cost, or complexity. Metal 3D printing is getting bigger in India, too, so you’ve got more options for both prototypes and real-world parts.

This guide covers what you need to know about 3D printing services in India. We’ll help you match your project to the right process, estimate costs, check out material properties, and find platforms that actually deliver. If you’re new or just want to get parts faster, there’s something here for you.

Key Takeaways

- India has FDM, SLA, SLS, and MJF 3D printing—each works best for different materials and applications.

- Costs depend on process, material, part size, and tolerances. Online platforms make rapid prototyping cheaper and faster.

- Pick suppliers by looking at their processes, material range, certifications, and if they really understand additive design.

What is 3D Printing and Why It Matters in 2026

3D printing creates objects layer by layer from digital files. It’s way faster for prototyping and gives you design freedom that old-school methods just can’t match. By 2026, it’s changing how Indian companies make stuff—lower costs, faster production, and wild shapes that used to be impossible.

Definition and Core Concepts of Additive Manufacturing

3D printing, or additive manufacturing, builds up objects by stacking thin layers of material based on a digital design. Start with a 3D model on your computer, slice it into layers, and the printer lays down each one until you have a finished part.

This works with plastics, metals, resins, and composites. Each new layer sticks to the last, making a solid shape.

Unlike traditional manufacturing, which cuts away from a block, 3D printing only uses what you need. That means less waste and cool features like hollow sections or internal channels you just can’t get with other processes.

You’ll need three things: a digital 3D model (usually CAD), a printer that fits your material, and the raw material—could be filament, resin, or powder.

Why 3D Printing is Transforming Modern Manufacturing

With 3D printing, you can go from design to real part in hours or days, not weeks. It’s easy to test different versions without spending on expensive molds or tooling.

Prototyping costs drop a lot—what used to cost thousands and take weeks can now be done overnight for a few hundred rupees.

Design freedom is a big deal. Things like internal lattices or weird organic shapes are suddenly affordable. That’s huge for aerospace and medical, where every gram and every custom fit matters.

Small batches make sense now, too. You don’t have to order thousands just to make tooling worth it—making ten custom parts costs about the same per piece as making a hundred.

Hybrid manufacturing is on the rise, mixing 3D printing with CNC machining to blend design freedom and tight tolerances.

3D Printing vs Traditional Manufacturing (CNC Machining, Injection Molding)

CNC machining carves parts from solid blocks using spinning tools. It’s great for precision (±0.01mm is common) and nice finishes, but you waste a lot of material. Internal features can be tricky or just not possible. CNC is best for precise metal parts in moderate quantities.

Injection molding pushes melted plastic into a mold. It’s super fast once you have the mold, but molds are pricey—₹50,000 to ₹5,00,000 or more. You need to make a lot of parts to make it worthwhile, and changing the design means a new mold.

3D printing wins for custom jobs, tricky shapes, and small batches. You can print one or a thousand parts with similar per-part costs, and there’s barely any waste. Downsides? It’s slower for big runs, you might see layer lines, and sometimes parts aren’t as strong as those made with other methods.

| Method | Best For | Cost Structure | Lead Time |

|---|---|---|---|

| 3D Printing | Custom parts, prototypes, low volumes | Low setup, moderate per-unit | Hours to days |

| CNC Machining | Precise metal parts, medium volumes | Moderate setup, moderate per-unit | Days to weeks |

| Injection Molding | High volumes, identical plastic parts | High setup, very low per-unit | Weeks for tooling, then seconds per part |

Overview of 3D Printing in India

India’s additive manufacturing scene is picking up speed. The market was about $92 million in 2024 and could top $350 million by 2030. More industries are jumping in, helped by government support and the growing need for custom solutions.

Growth of the Additive Manufacturing Market

The Indian 3D printing market is growing fast—22% to 24% yearly. That’s putting India on the global map, with the worldwide market expected to hit $60 billion by 2030.

Metal 3D printing is especially strong, growing by 28% each year. More manufacturers are realizing how much material and time they can save with this tech.

Most of the market is driven by startups and service providers. They handle everything from building printers to making materials and custom parts.

Key Regions and Industry Ecosystems

Big industrial hubs in India have built solid 3D printing ecosystems. ISRO and DRDO use it for aerospace, and companies like Tata and Mahindra are bringing it into their factories.

The Make in India initiative has helped boost local manufacturing. There’s even a national plan to develop 50 India-specific technologies for materials, machines, and software.

Healthcare and aerospace are key sectors. Medical device makers are using 3D printing for prosthetics, which really helps people in remote or low-income areas.

Market Trends and Industrial Adoption

Industrial use is up because the benefits are clear. You can cut prototyping costs by 40% and develop products 60-70% faster.

Automotive, aerospace, and healthcare are leading the way. They use 3D printing for quick prototypes, tooling, and real parts with complex shapes.

Desktop FDM printers are now affordable, so even small businesses and schools can try basic prototyping. New features like multi-material and multi-color printing are opening up more uses, from consumer goods to machinery.

Types of 3D Printing Processes

Every 3D printing technology builds parts layer by layer, but the details are different. FDM melts plastic, resin printers use light, powder-based systems fuse particles, and metal processes make tough, industrial-grade parts.

FDM (Fused Deposition Modeling)

FDM is the most common and budget-friendly method in India. It melts plastic filament and lays it down through a moving nozzle, one layer at a time.

You can use materials like PLA, ABS, PETG, and even filaments with carbon fiber or wood. Desktop FDM printers start at ₹15,000, while industrial ones go up to ₹20 lakhs.

Common uses:

- Prototypes and concept models

- Jigs and fixtures

- Custom, low-volume parts

- Education and hobby projects

FDM parts show visible layer lines. Accuracy is about ±0.5mm on cheaper printers, ±0.2mm on industrial ones. It’s good for big parts and quick changes, but the surface often needs sanding or smoothing.

SLA/DLP (Resin Printing for High Precision)

SLA uses a laser to cure liquid resin, layer by layer. DLP does the same but with a projector, which can be faster for some parts.

These printers give you the smoothest finish and the finest details. You can get layers as thin as 0.025mm and accuracy of ±0.1mm or better.

Materials include:

- Standard resins for prototypes

- Tough/flexible resins for testing

- Castable resins for jewelry and dental

- High-temp resins for engineering

Desktop SLA/DLP printers cost ₹30,000-3 lakhs, industrial ones ₹10-50 lakhs. Resins cost more than FDM filament—usually ₹3,000-8,000 per liter.

After printing, you need to wash parts in alcohol and cure them under UV light. It takes a bit longer but gives you pro-level results for medical models, jewelry, and precision prototypes.

SLS (Selective Laser Sintering)

SLS uses a laser to fuse nylon powder. The powder supports everything, so no extra supports are needed.

You can print a bunch of parts at once by packing them in the powder bed. SLS is great for small to medium batches. Parts are strong, durable, with a slightly grainy feel.

It mainly uses nylon (PA11, PA12) and blends with glass or aluminum. These resist heat, chemicals, and wear better than most FDM plastics.

Advantages:

- No need for supports

- Strong, functional parts for real use

- Complex shapes are no problem

- Stable dimensions

Industrial SLS machines cost ₹25 lakhs to ₹1 crore. Service providers typically charge ₹800-2,500 per cubic inch. Expect a lead time of 3-7 days from Indian suppliers.

MJF (Multi Jet Fusion)

MJF is HP's powder-based 3D printing tech. It works by depositing fusing and detailing agents across a nylon powder bed, then fusing the particles with heat.

This process is faster than SLS and gives you parts with more consistent mechanical properties. You'll notice better surface quality, less porosity, and improved dimensional accuracy compared to SLS.

Parts made with MJF have uniform strength in all directions. That makes them solid choices for functional applications and production runs.

| Feature | MJF | SLS |

|---|---|---|

| Surface finish | Smoother | Grainier |

| Speed | Faster | Slower |

| Cost per part | Lower for volume | Higher |

| Material options | Limited (mainly PA12) | More variety |

MJF machines cost between ₹40 lakhs and ₹1.5 crores. You’ll find service providers in cities like Bangalore, Pune, and Delhi.

Pricing usually falls in the ₹600-2,000 per cubic inch range, depending on order size. MJF is a good fit if you need production-quality plastic parts in batches of 50 to 10,000 units.

Automotive and consumer goods manufacturers in India are using MJF more and more for end-use parts and spares.

DMLS / SLM / LPBF (Metal 3D Printing)

These are all metal 3D printing processes that use lasers to melt metal powder layer by layer. DMLS, SLM, and LPBF are basically the same thing, with minor differences.

You can print with aluminum, titanium, stainless steel, Inconel, and tool steels. The parts are as strong—or stronger—than traditional metal components.

Applications in India include:

- Aerospace components and brackets

- Medical implants and surgical guides

- Automotive lightweight parts

- Tool and die inserts with conformal cooling

Metal 3D printers run from ₹1.5 to 8 crores. Service bureaus in industrial hubs charge ₹5,000-25,000 per cubic centimeter depending on the material.

Titanium and Inconel are pricier than aluminum or steel. The process needs inert gas and strict temperature control.

After printing, parts need support removal, heat treatment, and often CNC machining for final dimensions. Expect 2-4 week lead times in India.

Binder Jetting & Other Advanced Processes

Binder jetting uses a liquid adhesive to bond powder layers—no lasers or heat during printing. Works with metals, ceramics, or sand.

After printing, parts must be sintered in a furnace for full strength. It’s faster and generally cheaper than laser-based metal printing.

Indian foundries use binder jetting with sand to make molds and cores for casting. You can build larger parts and more pieces at once.

**Other specialized processes available

Industries Using 3D Printing in India

India’s 3D printing scene now has over 1,000 local players. The tech has moved past prototyping—full-scale production is happening, especially with "Make in India" pushing things forward.

Aerospace & Space Tech (ISRO ecosystem growth)

ISRO and private space companies use 3D printing for lightweight satellite parts and rocket engines. It cuts material waste by up to 70% compared to old-school machining, which is a big deal with expensive aerospace metals.

3D printing shines for tricky shapes like fuel injectors and combustion chambers—stuff you can’t machine easily. GKN Aerospace is leading the way in India, using the tech for flight demos and prototypes.

The sector gets shorter lead times—parts that took months now take weeks. Small batches make sense, so you can test multiple designs without blowing money on tooling.

Automotive & EV Prototyping

Car makers use 3D printing for quick prototypes, custom fixtures, and test parts. EV companies rely on it to rapidly try out new battery housings and cooling designs.

Lead times for prototype parts drop from 6-8 weeks to just 2-3 days. Major brands in India print jigs, fixtures, and assembly aids right on the shop floor.

It’s great for low-volume, customized parts like dashboards and brackets. EV startups use 3D printing to test aerodynamics and structure before investing in mass production tools.

Medical, Dental & Bio-printing

Healthcare providers use 3D printing for patient-specific surgical guides, dental aligners, prosthetics, and anatomical models. The Indian medical 3D printing market hit USD 0.75 billion in 2023, driven by demand for custom solutions.

You can make dental crowns, bridges, and orthodontic devices in-house, cutting production time from weeks to hours and saving money.

Surgeons use 3D-printed models to plan tough procedures, which helps improve outcomes and reduce surgery times. Bio-printing research is growing in India, but real-world clinical use is still mostly experimental. Custom prosthetics made this way cost 60-70% less than traditional ones.

Consumer Electronics & Robotics

Electronics makers use 3D printing for custom enclosures, brackets, and prototypes. It lets you test designs before investing in molds.

Robotics firms print structural parts, end effectors, and sensor housings. It’s easy to tweak designs after testing, without wasting money or waiting on suppliers.

Short production runs of custom electronics housings are now possible. Indian startups especially like the low barrier—print prototypes or small batches with no minimum order.

Defense & Strategic Manufacturing

Defense uses include spare parts for old gear, custom weapon accessories, and lightweight drone parts. On-demand printing helps fix supply chain problems for critical components.

You can make obsolete parts when suppliers are gone or minimum orders are too high. That keeps legacy equipment running a lot longer.

The Indian defense sector values 3D printing for field-repairable parts and quick equipment tweaks. There’s also less reliance on foreign suppliers, and classified parts can be made locally with better security.

Material Selection for 3D Printing

Picking the right material affects strength, durability, cost, and printability. Some materials are best for prototypes, others for tough engineering parts.

Polymers (PLA, ABS, Nylon, TPU, PETG, ASA)

PLA is the easiest to print and works well for prototypes and looks. Prints at 190-220°C, no heated bed needed. But it softens at 60°C and can get brittle, so skip it for functional parts.

ABS handles heat up to 100°C and is tougher than PLA. Needs 220-250°C and an enclosed printer to avoid warping. It smells during printing, so ventilate well.

Nylon is strong, flexible, and wears well. It soaks up moisture, so keep it dry. Great for gears and hinges.

TPU is flexible, like rubber. Use it for seals, gaskets, and phone cases. It prints slow and needs careful settings to avoid clogs.

PETG is easy like PLA, but tougher. It resists moisture and chemicals, and sticks together well. Good for functional parts needing some strength and flex.

ASA is like ABS but handles sunlight better. Use it for outdoor parts. Needs the same printer setup as ABS.

Engineering-Grade Composites (CF-Nylon, GF-Nylon, Ultem, PEEK)

CF-Nylon mixes carbon fiber into nylon for stiff, lightweight parts. Use a hardened nozzle—carbon fiber chews up brass ones.

GF-Nylon adds glass fibers for strength and stability. It’s cheaper than CF-Nylon but still tough. Expect a rougher finish than plain nylon.

Ultem is a high-temp plastic, good up to 170°C. Used in aerospace and medical. Needs industrial printers with hot chambers.

PEEK is super strong, handling up to 250°C and resisting chemicals and wear. Used in tough industrial and medical jobs, but needs a printer with a 150°C chamber.

Metals (Aluminum AlSi10Mg, Stainless Steel 17-4PH, Titanium Ti6Al4V)

AlSi10Mg is a lightweight aluminum alloy. You can heat treat it for better strength. It’s great for aerospace brackets and lightweight structures.

Stainless Steel 17-4PH resists corrosion and can be heat treated for high strength. Parts can hit 40 HRC hardness after aging. Works for prototypes, tooling, and end-use parts in tough spots.

Titanium Ti6Al4V is the king for strength-to-weight and is biocompatible, so it’s used for implants. It’s pricey and needs special DMLS or EBM printers.

Metal prints need post-processing—support removal, heat treatment, and maybe machining for tight tolerances. Stress relief is important to avoid warping.

Resin Materials (Standard, Tough, Flexible, High-Temp, Dental)

Standard resins give smooth finishes and fine details, but are brittle. Best for models, miniatures, and jewelry patterns.

Tough resins act like ABS, with more impact resistance. Good for functional prototypes that need to handle some stress. They cost more than standard resins.

Flexible resins make rubbery parts, from 50A to 95A hardness. Great for gaskets, grips, and wearable prototypes. Handle with care during cleaning and curing.

High-temp resins stay strong up to 238°C under load. Use for mold patterns, hot air/fluid testing, and under-hood car parts.

Dental resins are biocompatible for oral use. There are types for guides, aligners, dentures, and crowns. These need certification and special post-processing.

Material Sourcing & Availability in India

Indian suppliers stock common materials like PLA, ABS, and PETG. You can find these through online marketplaces and local distributors in big cities.

Prices for basic polymers fall between ₹600 and ₹1,200 per kg. Engineering materials like CF-Nylon and PEEK are harder to find locally.

You might have to import CF-Nylon and PEEK, which bumps up costs and adds 2-4 weeks to delivery. Some Indian manufacturers now make Nylon and TPU, but options are still limited.

Metal powders need special import licenses and careful storage. Only a handful of suppliers in India keep metal powders in stock, so most orders go through your printing service.

Quality certifications and powder recycling can differ a lot between suppliers. Resin availability is getting better, with local distributors carrying popular brands.

Standard and tough resins are easy to get. Specialized resins, like dental types, usually need to be imported.

Keep in mind, resins break down if exposed to light or heat, so storage is important.

3D Printing Costs in India: Complete Pricing Guide

3D printing costs in India depend on machine rates, material prices, and where you’re located. Part costs can be anywhere from ₹50 to ₹50,000, depending on process, size, and material.

Cost Per Part Estimation Model

There are four main cost buckets: material, machine time, labor, and post-processing. Material cost is based on part volume, material density, and per-kg price.

Machine time has its own hourly rate, which changes with the printer and technology. Labor covers file prep, setup, and part removal.

Post-processing means extra finishing—support removal, sanding, painting, and so on. For a typical FDM part (100cc, PLA), you might pay ₹80 for material, ₹120 for three hours of machine time, and ₹50 for labor.

To estimate costs, measure your part’s bounding box and support volume. Multiply total volume by material cost per cc, then add machine time for print duration.

Service bureaus usually tack on a 15-30% markup for overhead and profit.

Machine Rates by Process (INR pricing benchmark table)

| Process | Hourly Rate (₹) | Material Cost/kg (₹) | Typical Part Cost Range (₹) |

|---|---|---|---|

| FDM | 40-120 | 800-3,500 | 50-2,000 |

| SLA/DLP | 150-400 | 8,000-18,000 | 300-5,000 |

| SLS | 400-800 | 6,000-12,000 | 800-15,000 |

| MJF | 500-900 | 5,500-10,000 | 1,000-20,000 |

| Metal SLM | 2,000-4,500 | 25,000-60,000 | 5,000-50,000 |

| PolyJet | 600-1,200 | 15,000-35,000 | 1,500-12,000 |

Desktop FDM printers in the ₹10,000-₹20,000 range have the lowest running costs. Industrial printers cost more because of higher precision and certification needs.

Factors Affecting Pricing (Material, Layer Height, Post-Processing, Volume)

Material selection makes the biggest difference. PLA is ₹800-1,200 per kg, while PEEK can be a whopping ₹35,000 per kg.

Metal powders are even pricier—aluminum starts at ₹25,000, titanium alloys go up to ₹60,000 per kg. Layer height matters too.

Printing at 0.1mm layers takes twice as long as 0.2mm, so it costs more. Finer layers make for smoother parts but drive up the price.

Post-processing can double or even triple your base cost. Basic support removal is ₹100-500 per part.

Vapor smoothing for ABS can add ₹300-800. Metal parts needing heat treatment or machining might cost 150% more than printing alone.

Production volume brings discounts. One-off prototypes are expensive, but 50+ units can drop the per-part price by 30-60%.

Best pricing comes at 100-500 parts—beyond that, injection molding is usually cheaper.

Cost Optimization Strategies for Engineers

Want to cut costs? Try hollowing out parts where possible—it can save 40-70% on material.

Designing self-supporting shapes means you need fewer supports, which saves money.

Batching several small parts on one build plate spreads out machine costs. This trick can slash per-part expenses by half or more.

Orient parts to reduce height and print time. Don’t over-specify tolerances—if ±0.3mm is good enough, don’t ask for ±0.1mm.

Stick to standard materials unless you really need something exotic. And always get quotes from several suppliers—prices can vary a lot.

Our platform makes this easier: upload your CAD file and get instant costing in 5-10 seconds, powered by our own computational geometry and AI algorithms. Once you place an order, we connect you with the right manufacturing partner and keep you updated.

Regional Pricing Comparisons (Pune, Bangalore, Chennai, Noida)

Bangalore is the hub for industrial 3D printing, with 10+ service bureaus offering SLS, MJF, and metal printing. Lead times are 3-7 days. FDM services cost ₹50-80/hr, SLS rates are ₹500-750/hr.

Pune is about 15-20% cheaper than Bangalore, especially for auto and aerospace work. Metal printing rates are ₹1,800-3,800/hr, with 5-9 day delivery.

Chennai is great for high-volume runs, with FDM starting at ₹35/hr. There are 8+ certified facilities, but lead times are a bit longer (7-12 days). Large orders save 25-35%.

Noida covers the north, with prices between Bangalore and Chennai. There are 12+ suppliers, and turnaround is 4-8 days. MJF services are ₹550-850/hr, with strong rapid prototyping capabilities.

How to Choose the Right 3D Printing Service Provider

Picking the right 3D printing partner means looking at certifications, capabilities, quality checks, and a few warning signs.

Essential Certifications (ISO 9001, ISO 13485 for Medical, AS9100 for Aerospace)

ISO 9001 shows a provider has solid quality systems. They track defects and keep standards consistent.

For medical parts, look for ISO 13485. It means tighter controls and traceability.

AS9100 is a must for aerospace—it adds extra rules for risk and inspections.

Always verify certifications with certificate numbers and issuing bodies. Some providers just claim compliance, so double-check if you’re in a regulated industry.

Capability and Technology Evaluation

Different tech does different jobs. FDM is fine for prototypes, but not as smooth or strong as SLA or SLS.

Ask about their machines, build sizes, and layer resolutions. More HP Multi Jet Fusion machines? They can handle bigger orders.

Check if they stock engineering materials like PA12 or glass-filled nylon. Ask for sample parts—photos don’t tell the whole story.

Quality Control and Testing Methods

Good providers use calibrated tools to check part sizes. Do they provide inspection reports?

Material certificates matter, especially for engineering or regulated parts. First article inspections help catch mistakes before full production.

Some shops offer extra tests—tensile strength, chemical resistance, or surface roughness—if you need them.

Red Flags in Vendor Selection

Vague lead times show poor planning. Reliable providers give you clear timelines.

No material data sheets? They might be using cheap substitutes. Always ask for documentation.

Won’t sign NDAs or share references? That’s a bad sign.

Super low prices usually mean corners are being cut. If communication is bad during quoting, it won’t get better later.

Step-by-Step: Getting Your 3D Printed Parts Made

Getting a part made goes through four phases: prepping your digital files, setting print options and getting quotes, managing printing and quality checks, and finishing touches before delivery.

Phase 1: Design & File Preparation (STL, STEP, AMF)

Start with a 3D CAD model using tools like SolidWorks, Fusion 360, or AutoCAD. Export your design in a printer-friendly format.

STL is the default for most printers. STEP files keep more design info and are handy if changes are needed. AMF files support color and multi-materials but aren’t common in India.

Check your file for errors—holes, flipped normals, or non-manifold edges will cause problems. Free software like Meshmixer or Netfabb can fix most issues.

Wall thickness matters. FDM needs at least 0.8-1mm walls; resin printers can go as thin as 0.4-0.6mm. Design for the right tolerances—most 3D prints are accurate to about ±0.2-0.5mm depending on the process.

Phase 2: Orientation, Supports, Slicing & Quoting

Your supplier will orient your part for best strength, finish, and material use. Orientation also affects where supports are needed and how visible the layers are.

Supports hold up overhangs during printing but cost extra to remove. Designing with angles above 45 degrees can help skip supports.

Slicing software breaks your model into layers and generates G-code for the printer. Layer heights range from 0.05mm (for detail) to 0.3mm (for speed).

When requesting quotes, include:

- Material type and grade

- Layer height

- Infill percentage (for FDM)

- Quantity

- Delivery timeline

- Post-processing needs

Prices differ a lot. A small FDM part could be ₹200-500; the same part in SLS nylon might be ₹1,500-3,000.

Phase 3: Printing, QA & Post-Processing

Printing time really depends on the size, complexity, and technology you pick. For example, a 50mm cube can take 2-4 hours on FDM, or 8-12 hours if you go for high-res SLA.

The printer lays down material layer by layer based on your sliced file. FDM melts plastic filament, SLA uses UV light to cure resin, and SLS fuses nylon powder with lasers.

Most Indian print shops run jobs overnight for better machine use.

Once printing finishes, quality checks happen right away. Inspectors use calipers to check dimensions, look for layer adhesion issues, and make sure features came out right.

If a part fails, it gets reprinted for free by reputable suppliers.

Post-processing is next. This means removing supports and cleaning up the part.

FDM supports are snapped off or dissolved in chemicals. Resin prints get washed in isopropyl alcohol and cured under UV. SLS prints need depowdering with air and brushes.

Phase 4: Surface Finishing & Delivery

Raw prints show layer lines and sometimes need extra finishing, depending on your needs and budget.

Basic finishing just means removing supports and a quick sand. Parts still look “3D printed.”

Standard finishing involves sanding with finer grits for a smoother look. Premium finishing adds primer, paint, or special coatings for a more polished result.

Here are some common finishing options:

| Finish Type | Process | Typical Cost Increase | Lead Time |

|---|---|---|---|

| Sanding | Manual sanding, 120-400 grit | +15-30% | +1-2 days |

| Primer + Paint | Filler primer, spray paint | +40-80% | +2-4 days |

| Vapor Smoothing | Chemical vapor treatment | +50-100% | +1-3 days |

| Dyeing | Color penetration (nylon) | +20-40% | +1-2 days |

Metal plating and custom colors take longer and cost more. Budget an extra 3-7 days if you want those.

Most suppliers in India ship with couriers like Delhivery, Blue Dart, or DTDC. Delivery usually takes 2-5 days, depending on where you are.

Ask for bubble wrap or foam packaging to avoid damage in transit.

Prototyping and Low-Volume Production

3D printing cuts out tooling costs and speeds up product development in India. It builds parts layer by layer, so you can make one prototype or a few hundred units without much waste.

Benefits for Product Development

You can go from idea to prototype in a few days, not weeks. No need for expensive molds or tooling—just upload your file and print.

There are no setup fees, no minimum orders, and you’re free to change the design as you go. Each print costs about the same, whether you make one or a hundred parts.

It’s easy to test different versions of a part in the same week, get feedback, and tweak your design without worrying about cost. That helps you fix problems early, when it’s cheaper.

Material waste is way lower than with CNC machining, which cuts away a lot of extra material. With 3D printing, you use only what you need.

Case Studies from Indian Industry

Indian automotive suppliers use 3D printing for custom jigs and fixtures. These used to take weeks and big orders, but now they print them on demand.

Medical device startups in Bangalore and Pune print small batches for clinical trials and regulatory submissions. This avoids the big investment in injection molding until the product is proven.

Consumer product brands often print 50-200 units for limited releases or regional tests. The feedback shapes final design before they invest in mass production.

Limitations and Risks

3D printed parts don’t always match the strength of traditional ones, especially along the layer lines. You really need to test parts in the real world before relying on them.

Most prints need post-processing for a good finish. Sanding, coating, or vapor smoothing adds time and cost, so plan for it.

Production speed is a limit. Printing hundreds of parts takes much longer than injection molding. Above 500-1000 units, traditional methods are usually cheaper.

Part size is another constraint. Most industrial printers in India max out at about 400mm in any direction. Bigger parts need to be split and assembled, which isn’t always ideal.

Technology Trends Reshaping 3D Printing in 2026

The industry is moving from just prototyping to full-on manufacturing, thanks to automation, AI, and a push for sustainability. These changes are making 3D printing more practical for real production—and a bit more eco-friendly.

Full-Scale Production Using Additive Manufacturing

Manufacturers are now doing full production runs with 3D printing, not just prototypes. You can make end-use parts at scale, skipping the tooling costs.

Metal 3D printing is now reliable enough for aerospace and auto parts. You get complex shapes that are tough or expensive to make any other way.

Main perks:

- No minimum order size

- Easy customization—no retooling

- Complex parts mean fewer assembly steps

- Less material waste

Printing locally cuts shipping costs and speeds up delivery. You get parts closer to where you need them, which also shrinks your carbon footprint.

AI-powered Print Optimization & Automation

AI now monitors print quality in real time and tweaks settings automatically. You get fewer failed prints and less waste.

AI tools analyze your design and suggest the best orientation, supports, and materials. It saves you a lot of prep time and learns from every print.

AI helps with:

- Spotting errors on the fly

- Using less material

- Speeding up prints

- Predicting maintenance needs

Some systems pause prints if they spot a problem, so you don’t waste more material. You don’t have to babysit the machines all day.

Robotics & Lights-Out AM

Robots now handle tasks like support removal and part cleaning. You can run a bunch of printers with barely any staff.

Lights-out manufacturing means printers run overnight or on weekends with no one there. Automated systems load materials, start jobs, and take out finished parts.

You’ll see robotic arms moving parts between stations and keeping things flowing. This makes production more consistent since robots don’t get tired or sloppy.

Sustainable & Recyclable Materials

New recyclable filaments and powders let you reuse failed prints and supports. Recycling can cut material costs by 20-30%.

Bio-based plastics from corn starch or algae now match the performance of regular plastics, but break down naturally later. You can hit your green goals without sacrificing quality.

Sustainable material options:

- Recycled PET (like old bottles)

- Plant-based polyamides

- Reusable metal powders

- Biodegradable supports

Metal powder recycling is way better now. You can reuse up to 95% of leftover powder, which really cuts costs for metal printing.

Common 3D Printing Challenges (and Solutions)

3D printing in India faces issues like warping, layer adhesion trouble, surface finish problems, and supply chain delays that can mess with your timeline.

Warping, Layer Adhesion & Dimensional Accuracy

Warping happens when parts curl up or lift off the bed, usually from uneven cooling. ABS is especially tricky here. Try a heated bed, glue stick, or enclosing your printer to keep temps steady.

Poor layer adhesion means layers peel apart. This is often from low nozzle temps or printing too fast. Bump up your nozzle temp and slow down the print speed to help layers bond.

If your parts don’t match the CAD dimensions, it’s probably a calibration issue. Check your steps per mm, level the bed, and run test prints to dial in your settings.

Surface Finish Issues

Layer lines are the most common complaint. Reducing layer height helps, but it makes prints slower. Lower print speeds and better retraction settings can also cut down on blobs and stringing.

Post-processing like sanding works great for PLA and PETG. Vapor smoothing with acetone gives ABS a shiny finish. Primer and paint make parts look pro.

Support marks and gaps are a pain. Trim them with a hobby knife, fill with wood filler or epoxy, and sand smooth before painting.

Material Limitations & Mechanical Strength

PLA is easy to print but weak for real-world use. It softens above 50°C and snaps under impact. PETG is tougher and handles more heat.

For serious strength, go for nylon or carbon fiber-filled filaments. These need higher temps and hardened nozzles, but hold up better.

Orientation matters. Parts are weakest along the Z-axis (layer lines). Try to orient them so stress runs along the layers, not across. Thicker walls and higher infill help, but use more material and time.

Supply Chain & Lead Time Challenges

Material availability varies a lot. PLA and PETG are easy to get, but specialty filaments might be out of stock or take weeks to arrive.

Some advanced materials still need to be imported, which adds cost and delays. Domestic suppliers are growing, but the selection isn’t as big yet.

Printer parts like nozzles and belts need replacing now and then. These aren’t always in stock locally, so keep spares on hand and find a good supplier for your printer model.

Why Choose Partwork.io for Your 3D Printing Needs

Partwork.io makes it easy to find reliable 3D printing suppliers in India. You get instant pricing in 5-10 seconds using our proprietary computational geometry and AI algorithm.

Just send us your order—we’ll connect you with trusted manufacturing partners, show you transparent pricing, and make sure your parts are made to spec. Multiple technologies and materials, all in one place.

Platform Advantages

Partwork.io makes procurement a lot less painful. Instead of chasing different suppliers, you just upload your CAD files and see instant pricing—usually within 5-10 seconds—thanks to our proprietary computational geometry and AI algorithm.

You get clear pricing upfront. No hidden fees or surprises. That helps you budget better and decide faster.

There's a dashboard to track every order in real time. All your project details and timelines stay organized, and you don't have to manage endless email threads with suppliers.

Materials & Technology Capabilities

We connect you to manufacturers with FDM, SLA, SLS, and metal 3D printing. You can pick the process that fits your part best—no need to settle for just one option.

Materials available include:

- Standard plastics: PLA, ABS, PETG

- Engineering-grade: PA6, PC, TPU

- Advanced composites: Carbon fiber blends

- Specialty resins: Bio-compatible, production-grade

- Metals: For industrial applications

Each material lists specs and best uses, so you can match them to your requirements. Prototyping and low-volume production are both supported.

Quality Assurance & Supplier Network

All suppliers are vetted before joining. They have to prove their capabilities and stick to quality standards, so you don't get stuck with bad parts.

If something's off with your order, the platform steps in to fix it. There's a quality guarantee on every order.

You can see ratings and feedback from other engineers for each supplier. That peer info makes picking the right one much easier.

Get Started Today

Signing up is quick—usually under five minutes. Upload CAD files (STL, STEP, OBJ); you'll get a quote in seconds.

Try a single prototype if you want. No minimum order or membership fees. Payment's secure, and you only pay after approving the quote and timeline.

Frequently Asked Questions

Find answers to common questions about this topic

FDM is the most common—good for prototyping and small batches. It melts plastic filament and builds layer by layer.

SLA uses UV light and resin for finer details and smoother finishes, often for prototypes or casting patterns.

SLS fuses powder (like nylon) with a laser. Parts are strong and don't need support structures.

Metal 3D printing (DMLS, binder jetting) is growing for aerospace and tooling. You'll need a specialized service for metals.

Material choice affects cost and part performance. PLA is cheap (Rs 800-1,200/kg) but not very strong. ABS and PETG cost more (Rs 1,500-2,500/kg) and are tougher.

Specialty materials (carbon fiber, high-temp) can go above Rs 8,000/kg. SLA resins range from Rs 6,000-15,000/liter. Metal powders are the most expensive (Rs 15,000-50,000/kg).

FDM: Rs 3-8/gram. Complex parts cost more. Rush jobs add 20-50%.

SLA: Rs 8-15/gram. Smoother finish, but more post-processing.

SLS: Rs 15-30/gram. No support removal needed; minimum order may apply.

Metal: Rs 50-200/gram, plus setup and machining. Bulk orders save money.

Check if the supplier has the right printers and materials. Ask for sample parts to see quality first-hand.

Look for experience with your industry. References or case studies help.

Review lead times and capacity. Make sure they can handle your order size.

Certifications (like ISO 9001) matter for some industries. Ask about documentation and traceability if needed.

Multi-material and color printing are picking up. You can get parts with different materials in one go.

Large-format FDM printers are more available. Bigger parts, fewer assemblies.

AI-powered slicing software is reducing print failures and waste.

Sustainable materials and recycling are gaining ground. Some suppliers recycle failed prints.

Hybrid machines combine 3D printing with CNC for complex, low-volume parts.

You’ll need to register your business with local authorities under the right category. If you’re running a manufacturing setup, you might also need approval from the state pollution control board.

Fire safety clearance is a must, especially if you’re using flammable materials or heavy-duty equipment. Make sure your workspace has proper ventilation, since some printing processes can release fumes or dust.

Keep Material Safety Data Sheets (MSDS) for every material you use. These sheets tell you how to handle stuff safely and what to do if things go wrong.

If you’re working with clients, contracts should clearly cover who owns the parts and how you’ll keep things confidential. Sometimes, clients will want you to delete their digital files after you’re done.

Labor laws kick in once you hire people for printing or finishing work. You’ll also want insurance in case of injuries or equipment issues.

Don’t forget about waste rules. Used materials and chemicals like resins need careful handling and proper disposal. Keep records of how you manage waste, just in case you’re asked.